Counting and Sorting Machine for Packing Line

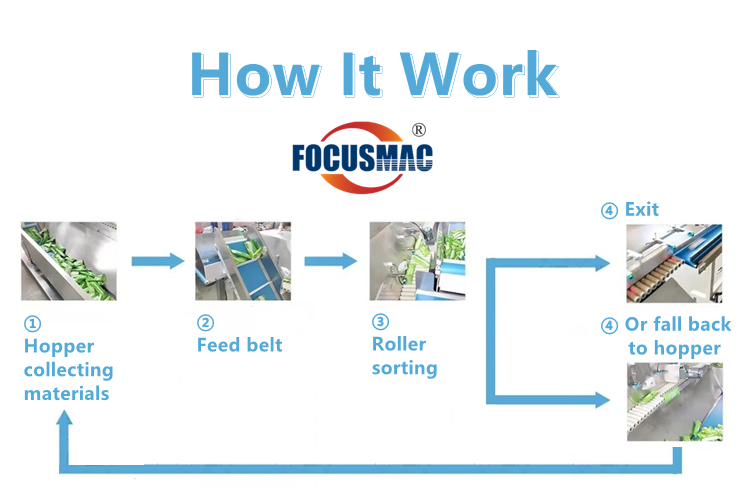

The automatic Counting and Sorting Machine can be connected with the box filling machine to complete the entire finishing process of the irregular accumulation of materials from concentration to dispersion and then to the sequential placement. After the material is poured into the storage bin, the bin conveyor belt moves to transfer the material to the low speed roller. Through the operation of low, medium and high speed rollers, the material is sent out of the bag sorting machine one by one. The sent materials enter the packing machine to complete the packing process of the next step according to the form or order of packaging needs or stack.

Counting and Sorting Machine for Packing Line

Our Advantages

1. Auto storage, loading, sorting, simple structure, save space.

2. Cabinet body design, easy to clean.

3. Functional modular design, easy maintenance.

4. Large hopper easy to feed materials.

5. Conveyor belts center positioning to prevent belt deviation.

6. Servo special direct connection to ensure that the servo kinetic energy and the execution belt, roller seamless linkage, to ensure accurate control.

7. Bag roller servo motor drive, roller adopts continuous bottom noise gear transmission, low noise.

8. Rollers are anti-static and anti-dust, bags will not slip while running.

9. Photoelectric sensor monitoring feedback, accurate adjust speed, bag stacking probability less than 0.1%.

10. The machine frame is made of 304 stainless steel.

Specification

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Details Images